Electromagnets

-

AC916ME05

51 mm × 70 mm × 85 mm

Surface mounting: 24 V DC

Holding force – 20 kg

Swivel anchor plate

Door status detection -

AC916ME07

51 mm × 70 mm × 85 mm

Surface mounting: 24 V DC

Holding force – 20 kg

Swivel anchor plate

Door status detection -

AC916MG

30,5 mm × 70 mm × 85 mm

Surface mounting

ABS housing

24 V DC

Holding force – 20 kg

Flat anchor plate -

AC918MEXX

80 mm × 110 mm × 128 mm

Floor mounting

24 V DC

Holding force – 40 kg

Flat anchor plate -

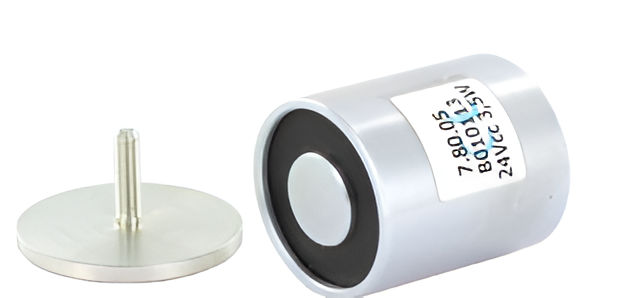

BEM10

Diameter: 30 mm

Mount: M4

Holding force: 12 kg

Locking: Power OFF

Power consumption: 3.5 W

Voltage range: 12–220 V DC

Standard voltage: 24 V DC -

BEM11

Diameter: 42 mm

Mount: M6

Holding force: 20 kg

Locking: Power OFF

Power consumption: 3 W

Voltage range: 12–220 V DC

Standard voltage: 24 V DC -

BEM12

Diameter: 48 mm

Mount: M6

Holding force: 50 kg

Locking: Power OFF

Power consumption: 3.5 W

Voltage range: 12–220 V DC

Standard voltage: 24 V DC -

BEM13

Diameter: 75 mm

Mount: M6

Holding force: 180 kg

Locking: Power OFF

Power consumption: 20.5 W

Voltage range: 12–220 V DC

Standard voltage: 24 V DC -

BEM3

Diameter: 30 mm

Mount: M6

Holding force: 12 kg

Locking: Power ON

Power consumption: 2.5 W

Voltage range: 12–220 V DC

Standard voltage: 24 V DC -

BEM4

Diameter: 40 mm

Mount: M6

Holding force: 40 kg

Locking: Power ON

Power consumption: 4 W

Voltage range: 12–220 V DC

Standard voltage: 24 V DC -

BEM5

Diameter: 50.8 mm

Mount: M8

Holding force: 55 kg

Locking: Power ON

Power consumption: 5 W

Voltage range: 12–220 V DC

Standard voltage: 24 V DC -

BEM6

Diameter: 63 mm

Mount: M8

Holding force: 145 kg

Locking: Power ON

Power consumption: 10 W

Voltage range: 12–220 V DC

Standard voltage: 24 V DC

Electromagnets – powerful solutions for industry and automation

Electromagnets play a key role in many modern technological systems. They are used to create a strong magnetic field when an electric current is applied, making it possible to hold, lock or lift metal objects with high precision. Their flexibility and reliability make them an obvious solution in everything from industrial automation to safety devices.

High holding force for demanding applications

Våra effektiva elektromagneter är utformade för att ge maximal hållkraft när de används mot en plan yta av tillräcklig tjocklek. För bästa funktion bör den hanterade delen ha en dimension som är lika stor som, eller större än, elektromagnetens hållyta. Rekommenderad minsta materialtjocklek framgår i respektive produkts datablad.

Two holding power options:

- Powered holding force – from 120 N to 5500 N. Ideal when the electromagnet only needs to hold under power supply.

- Currentless holding force (permanent magnet) – from 120 N to 2000 N. Perfect when you need protection even in the event of a power outage.

Användningsområden för elektromagnet

Electromagnets are particularly popular in the following areas:

- Access control – such as electric strikes, door magnets and access control systems.

- Safety – where reliable locking is required even during downtime.

- Automation projects – where fast and controlled magnetic functions are needed in machines or robotics.

Accessories for optimized function

For the BEM3, BEM4, BEM5 and BEM6 models, we offer matching holding plates and accessories. These help create optimal contact between the electromagnet and the surface, which improves holding force and increases the reliability of the system.