Brushless motors

Brushless DC motors (BLDC motors) are electric motors that operate without mechanical brushes, which provides longer life, higher efficiency and quieter operation compared to traditional brushed motors. Thanks to their high precision and low maintenance requirements, they are used in everything from power tools and drones to industrial automation and electric vehicles. Brushless technology enables compact designs with high performance and is ideal for applications where reliability and energy efficiency are crucial.

-

Brushless Motor B4S12-2109

Weight: 18g

Nominell spänning: 7.4 V / 12.0 V

Max vridmoment: 5.80 mNm / 6.05 mNm -

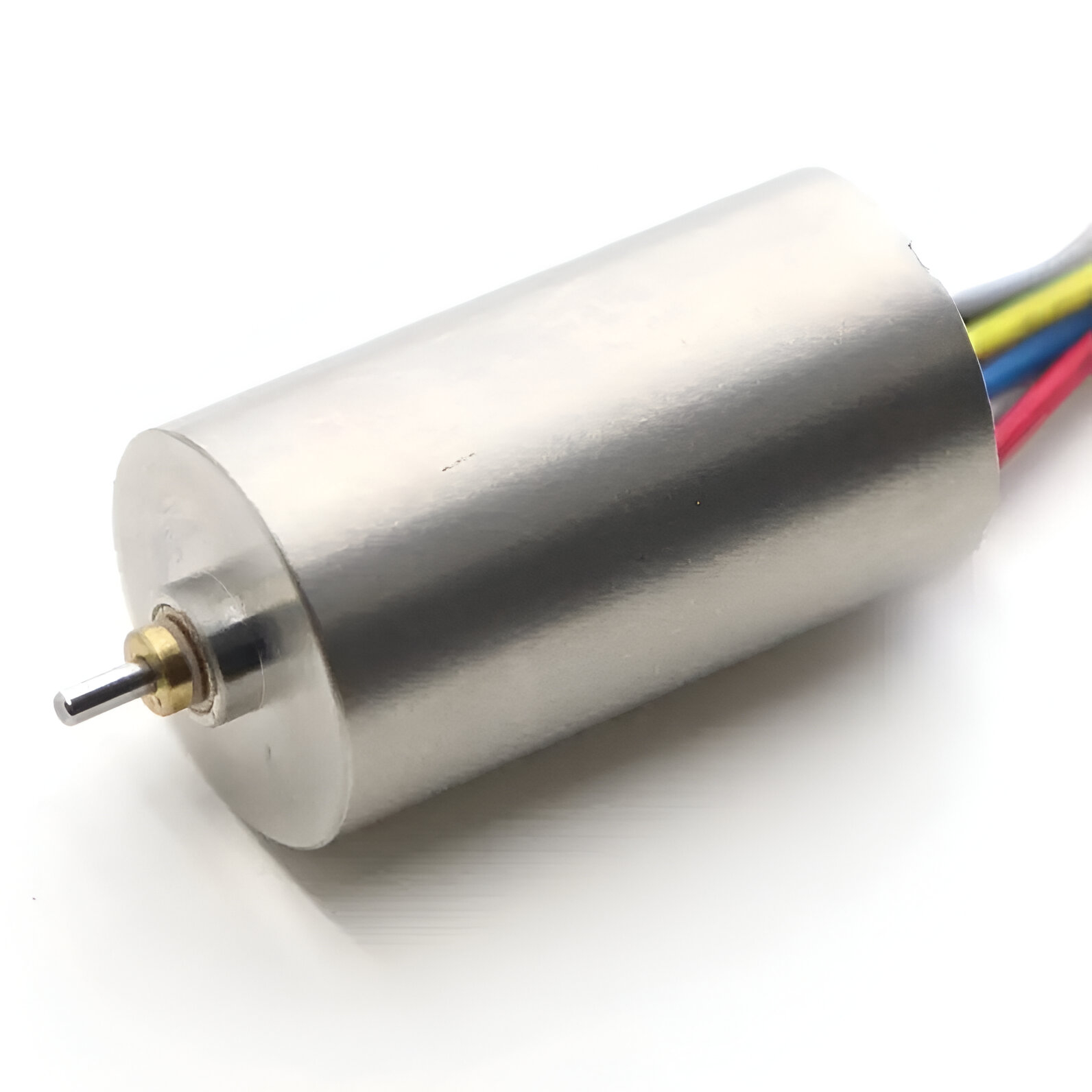

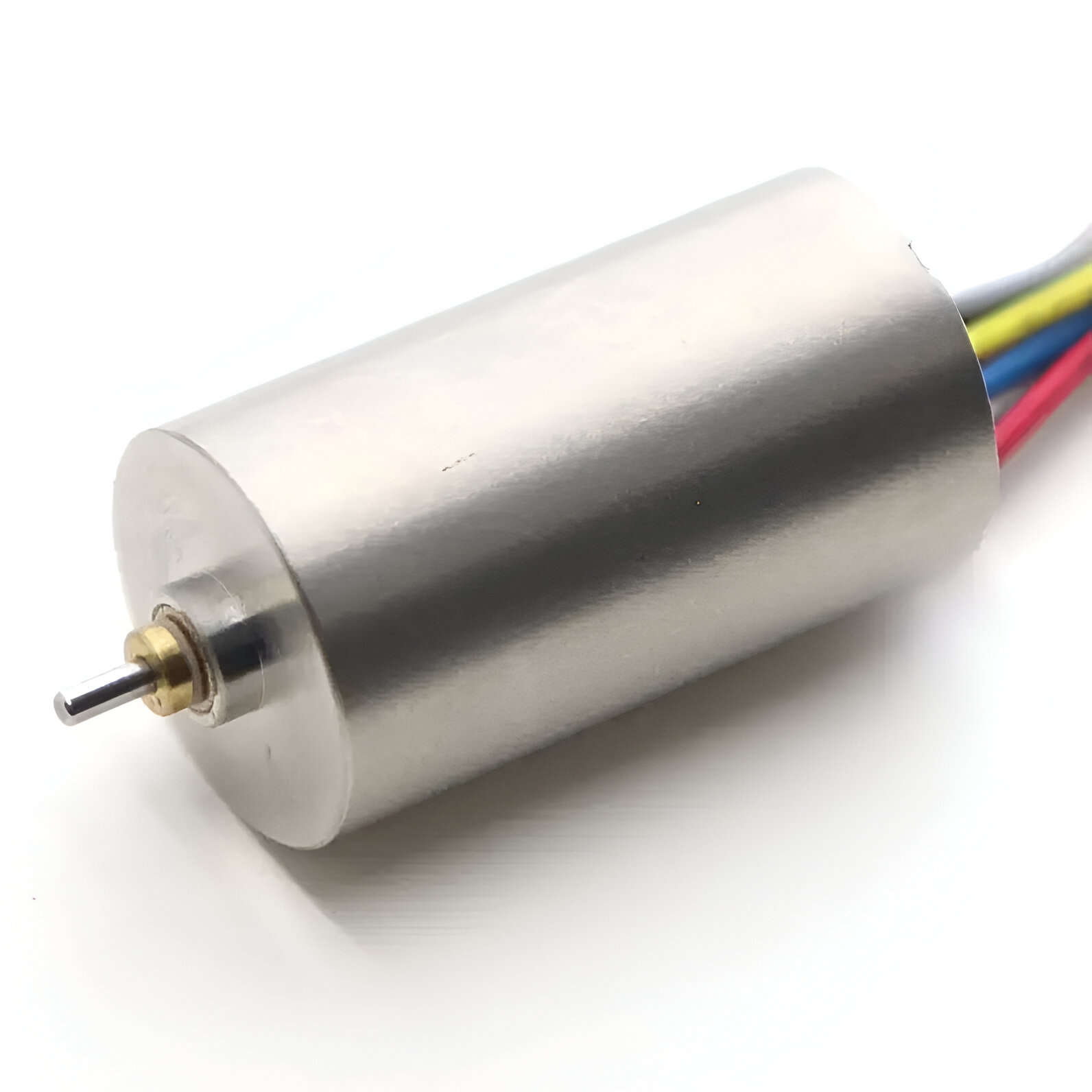

Brushless Motor B4S22-3210

Diameter: 22 mm

Längd (motor): 32 mm

Vikt: 72 g

Nominal voltage: 24 V

Max torque: 22 mNm -

Geared Brushless Motor B4S12-2108

Diameter: 12 mm

Weight: 18g

Nominal voltage: 1.83 mNm (7.4 V) / 1.60 mNm (12.0 V)

Max torque: 5.80 mNm (7.4 V) / 6.05 mNm (12.0 V)

How a brushless motor works

In a brushless motor, the rotating magnetic field is generated electronically via a control circuit. The coils are located in the stator and the rotor consists of permanent magnets. The commutation – i.e. the switching of current direction – is carried out using electronics and often using Hall sensors. This allows the motor to be operated with high precision and without physical contact-dependent parts that wear out over time.

The advantages of brushless motors

Brushless motors offer high energy efficiency because almost all of the electrical energy supplied is converted into useful motion. They are quiet and generate very little heat compared to brushed motors. Since there are no brushes to replace, they are virtually maintenance-free. This makes them a cost-effective and sustainable choice, especially when operating for many hours a day.

Applications for brushless motors

Brushless motors are used in a wide range of applications: from fans, pumps, electric vehicles and drones to medical devices, laboratory equipment, automation solutions and robotics. Their reliability and compact size make them a key component in modern systems where performance and precision are essential.

Examples of our brushless motors

At Elektrokomponenter we offer a wide range of brushless motors – from very small micro motors to powerful models with high rotation speed. There are variants with built-in sensors for precise positioning as well as sensorless motors for easier control. We also have motors that are combined with gears to provide increased torque without taking up more space.

How to choose the right brushless motor

For the right choice of brushless motor, you should consider:

- Voltage & Drive – choose the drive voltage (e.g. 12V or 24V DC) that matches your control system.

- Speed and torque – choose a motor with the right combination of rpm and power for your torque needs.

- Compact format & sensors – micromotors with or without hall sensors allow adaptation to space and positioning needs.

- Control – brushless motors require a motor controller (ESC or servo driver), such as our PSV24-05E which handles sensored and sensorless operation.

- Operating environment – select enclosure class, IP protection, temperature range and vibration requirements in relation to your application.

Technical documentation and support

All of our brushless motors come with clear documentation such as data sheets and drawings. We are happy to help with dimensioning, product selection and support for integration into control systems. Whether you are working on prototyping or scaling up a series production, we can help you find the right solution.

Frequently asked questions about brushless motors

What is a brushless motor?

A brushless motor is an electric motor that uses permanent magnets in the rotor and has coils in the stator. It lacks carbon brushes, which reduces wear, noise, and maintenance requirements.

How does a brushless motor work?

The motor is controlled by an electronic commutator that switches the direction of current in the coils, often using Hall sensors. This creates a rotating magnetic field that drives the rotor without physical contact.

What are the advantages of brushless motors?

Brushless motors have a longer lifespan, are more energy efficient, generate less heat and are quieter than brushed motors. They are also maintenance-free and suitable for continuous operation applications.

What applications are brushless motors suitable for?

They are used in electric vehicles, fans, pumps, drones, medical devices, industrial automation and robotics – all applications where quiet and precise operation is required.

Are there different types of brushless motors?

Yes. There are sensored brushless motors for precise position control and sensorless motors for simpler applications. Many can also be combined with gears for higher torque.

What is the difference between brushless and brushed motors?

Brushed motors use carbon brushes to create contact between the stator and rotor, which leads to more wear and noise. Brushless motors are electronically controlled and have no moving contact points, making them more durable and efficient.

How to choose the right brushless motor?

Choose a motor based on voltage, speed, power, torque and environmental requirements. Also consider whether you need sensor feedback, a gearbox or a compact format. Please consult us for the right choice.