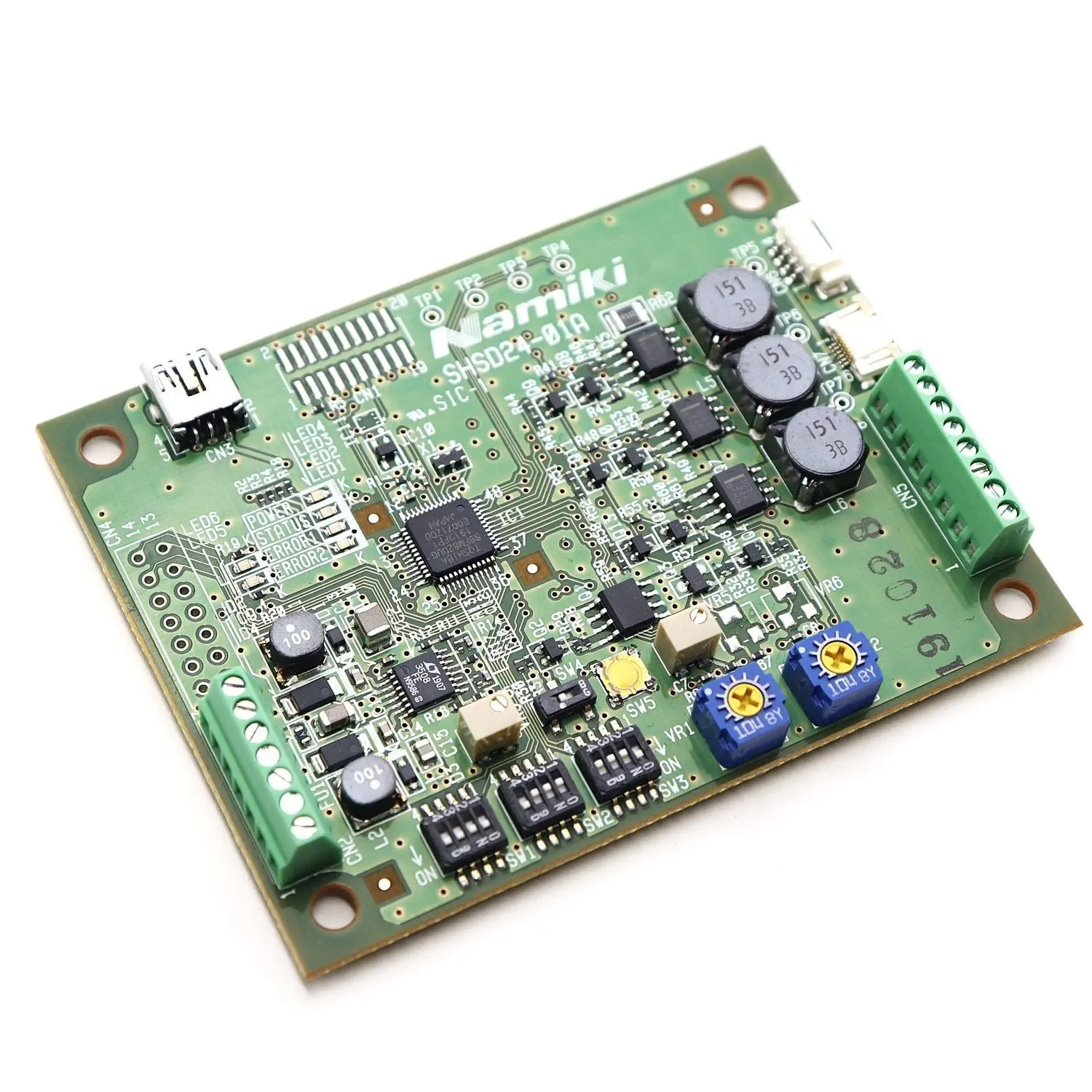

Motor control

Orbrays varianter av motorstyrningslösningar är utvecklade för att ge exakt kontroll över hastighet, position och vridmoment i mikromotorer. Sortimentet inkluderar både servodrivare och borstlösa motorstyrningar och tillbehör anpassade för företagets kompakta kärnlösa och borstlösa motorer. Genom att kombinera små dimensioner med avancerade kommunikationsgränssnitt som USB, RS485 och EtherCAT, erbjuder dessa enheter effektiv och flexibel styrning även i komplexa fleraxliga system.

-

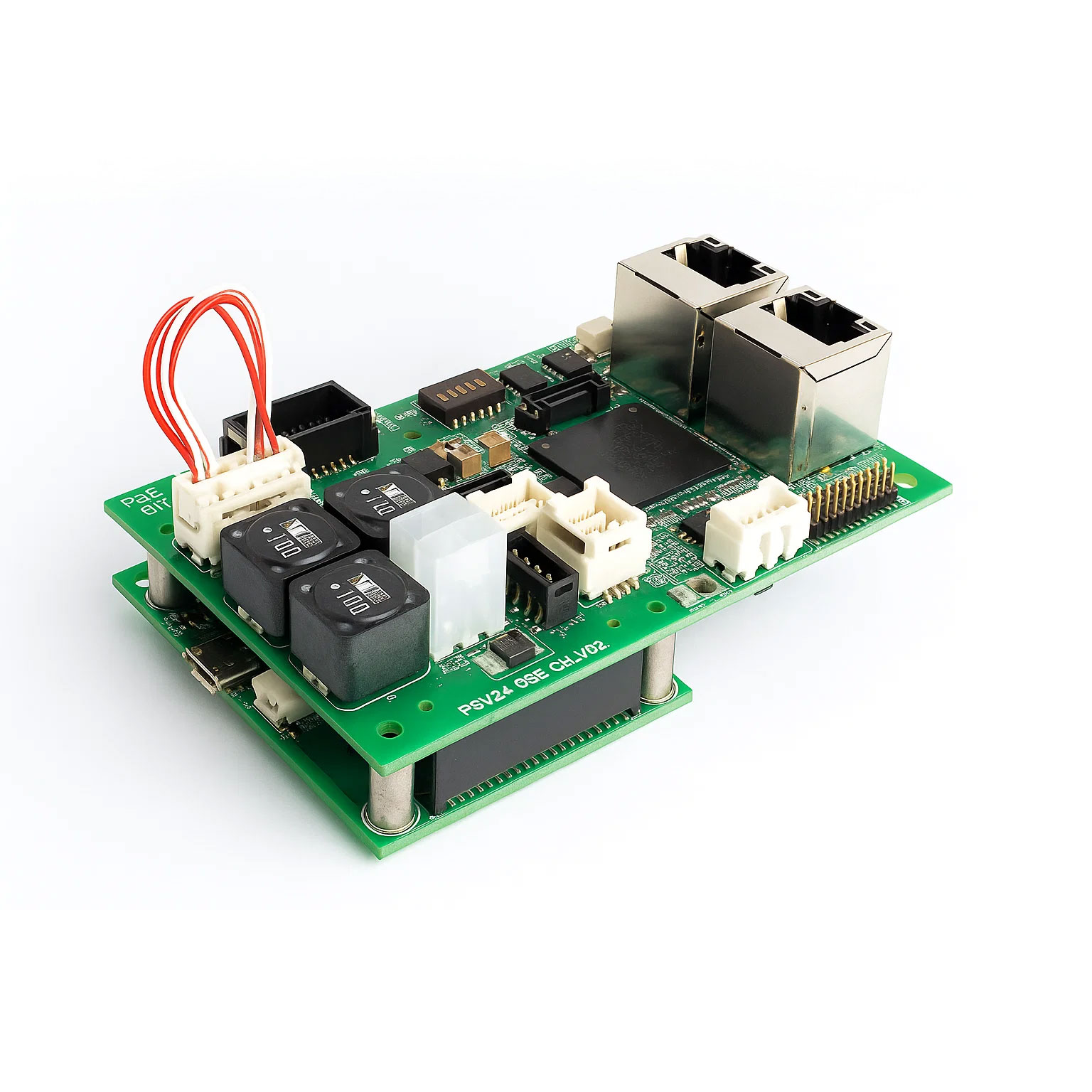

PSV24-05E

Dimensions: 90 x 58 x 30 mm

Control method: Position, speed, current (torque)

Compatible motors: Brushless motors, coreless motors

※ Encoder required as an option

※ Not compatible with sensorless motors -

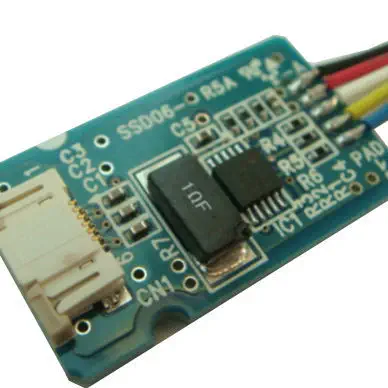

SSD06-R5A

Supply voltage: VCC 1.8 / 3.0 / 5.5 V

Current consumption: 5 / 10 mA

Output current: 0.5 A

Input voltage for direction of rotation (clockwise / Low): 0.0 – 0.5 V

Motor control for small motors

Efficient motor control is essential for controlling the speed, direction and torque of small electric motors. Whether you work with automation solutions, medical technology or portable devices, the right control system can improve precision, reduce energy consumption and extend the life of your equipment.

How electronic control works

A control board acts as an interface between the power source and the motor. By adjusting the intensity of the current using, for example, a PWM signal or square pulse, you can control the motor speed and direction of rotation. Some systems also offer feedback via sensors for precise position control and acceleration.

Compact solutions for limited spaces

Many applications require motor control in a minimal form factor. Our control boards are designed for small motors and are used in micromechanics, laboratory equipment and battery-powered systems. They offer smooth operation with low power consumption, even in environments with high demands on stability and reliability.

Advantages of modern control systems

Modern control systems enable quiet, precise and energy-efficient operation. Built-in features such as overcurrent protection, voltage adaptation and sensorless operation make installation easy and safe, while optimizing motor performance.

Is motor control right for your application?

If your solution requires controllable motion, adjustable speed or controlled stopping, motor control is a must. We help you choose the right control board based on power, voltage, communication needs and environmental conditions.

Support and documentation

All products are delivered with clear documentation – data sheets, wiring diagrams and technical specifications. If you need help with dimensioning or integrating motor control into your design, we are happy to provide expert support.

Frequently asked questions about motor control

What is motor control?

Motor control is the process of controlling the movement of an electric motor – that is, speed, direction, acceleration and sometimes even position. It is done using electronic control cards or control modules that adapt current and voltage to the motor.

When do you need motor control?

You need motor control when a motor needs to be controlled more precisely than just starting and stopping. This is common in automation systems, robotics, medical technology, laboratory equipment, and other applications where motion must be adapted to function or environment.

What types of motors can be controlled?

Common electronically controlled motors include brushed DC motors, brushless motors (BLDC) and servo motors. Each type requires its own specific type of control system.

What is the difference between sensorless and sensor-equipped motor control?

Sensorless motor control controls the motor without sensing the rotor position, which simplifies the design but can result in lower precision. Sensor models, for example, use Hall sensors to provide feedback and enable more precise positioning and soft start/stop.

How do you choose the right motor control?

You should consider the motor type, voltage, power, rotational speed, application and environment. Whether you need features such as braking, soft start or overcurrent protection will also affect your choice of control board.

Can you control multiple motors with one control board?

Some motor controllers are designed for single motors, while others can handle multiple motors simultaneously. It depends on power requirements, synchronization, and how much individual control you need per motor.