Encoders

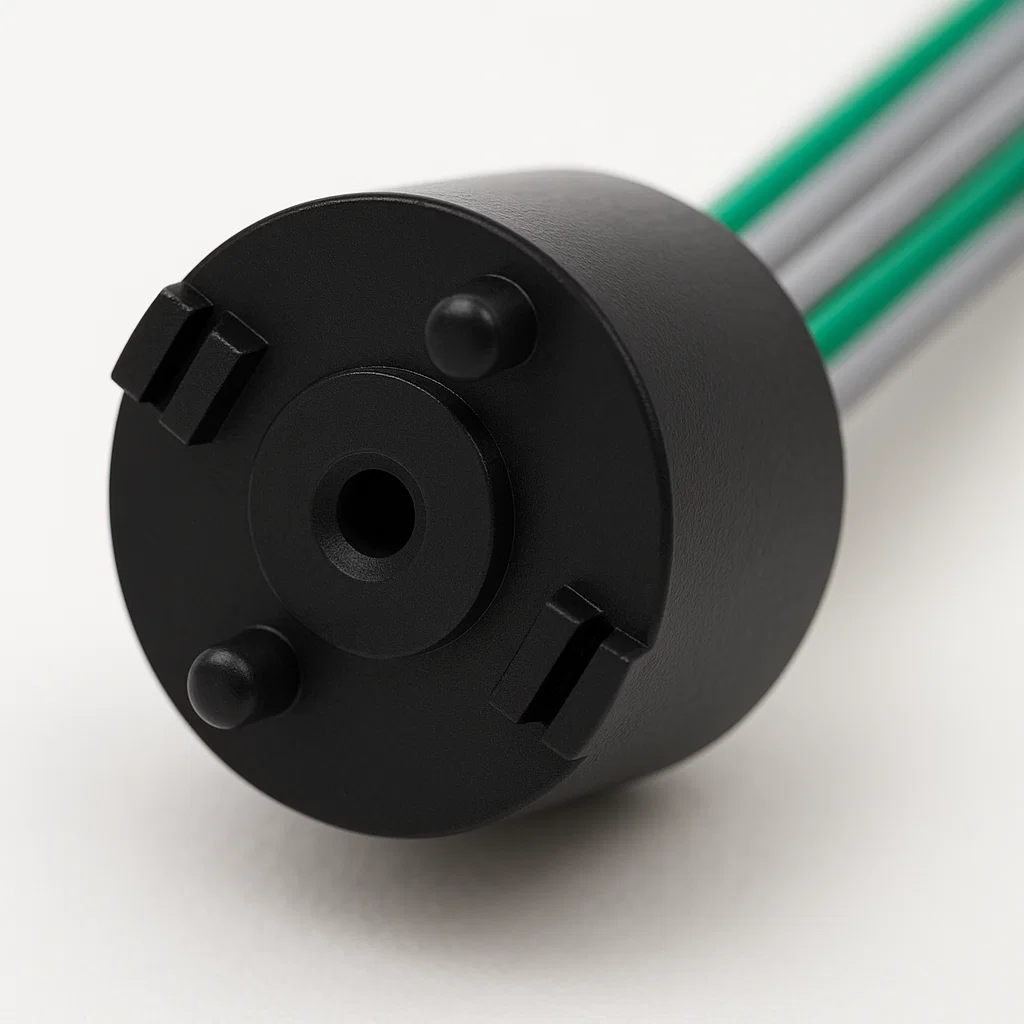

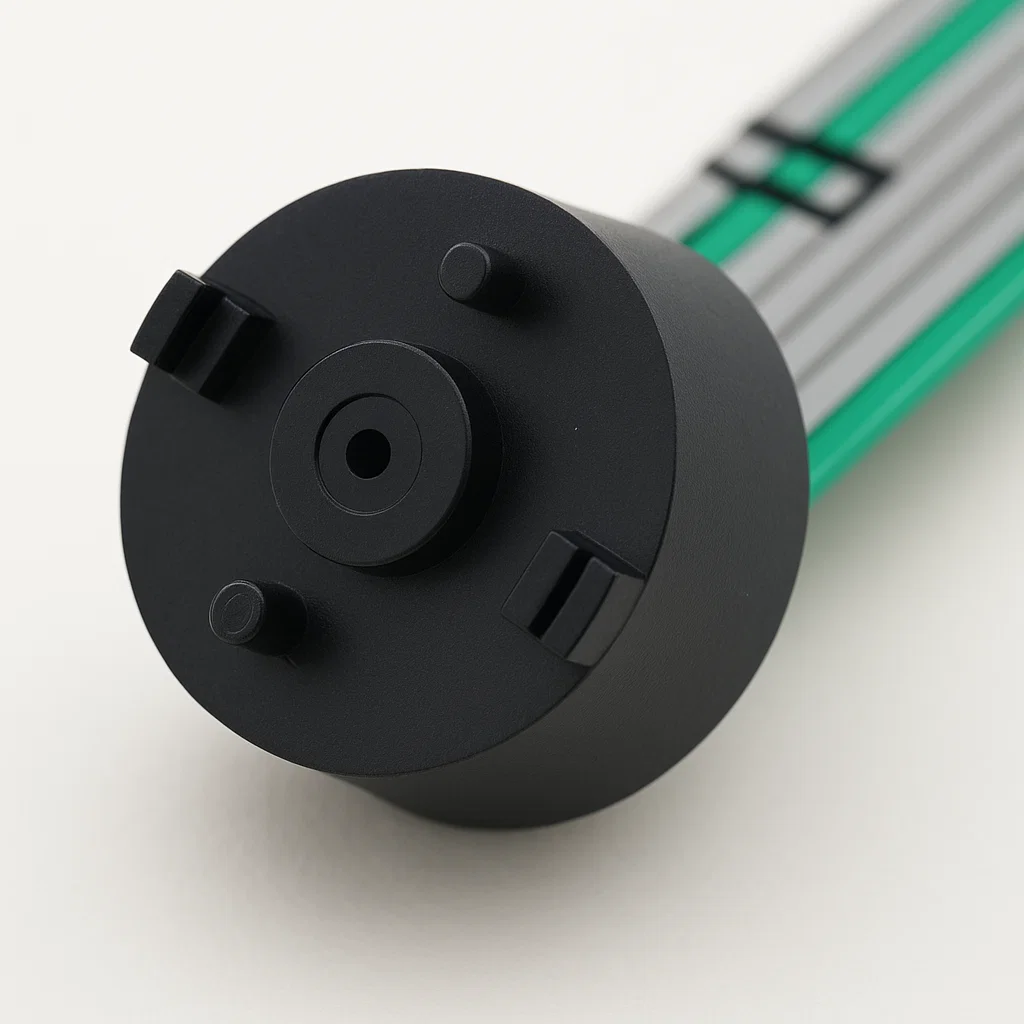

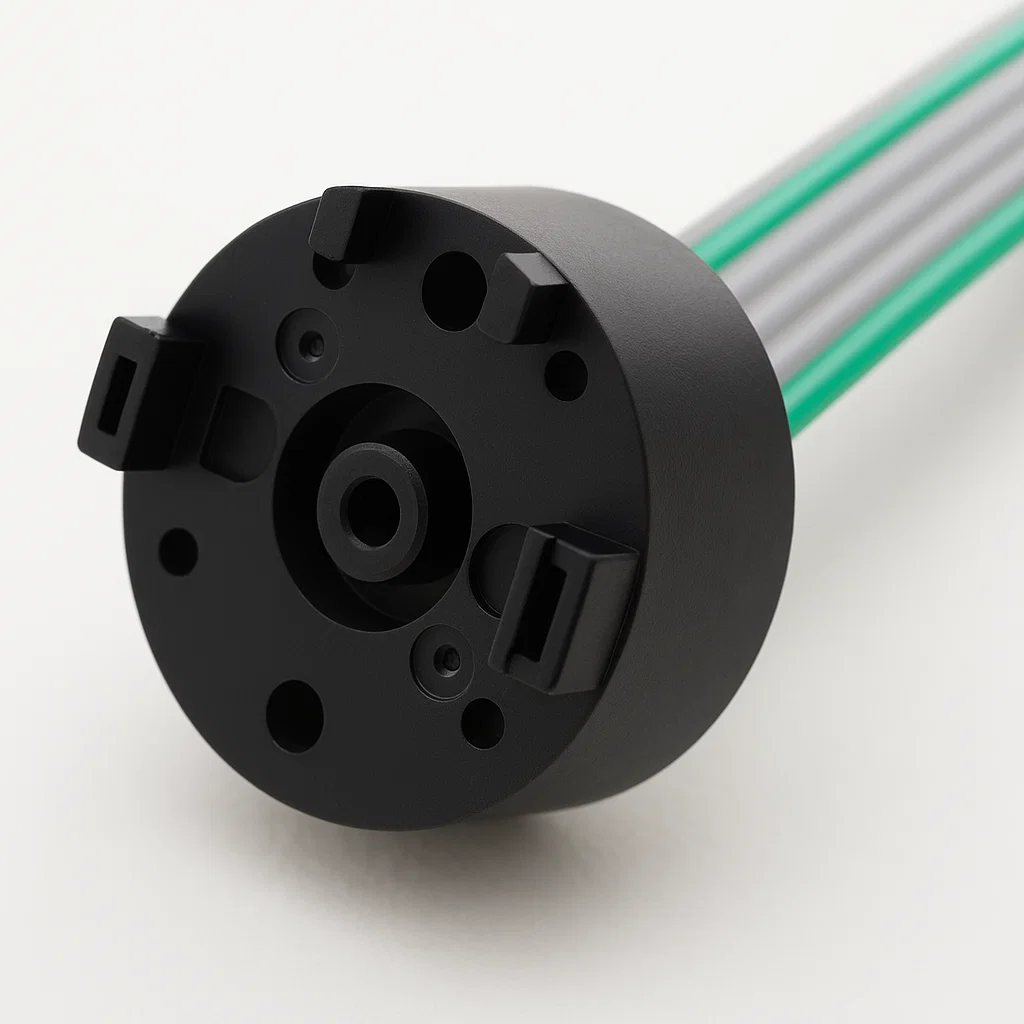

Elektrokomponenter offers a wide range of compact motor encoders from Orbrays that are specifically designed to integrate directly with their DC motors. By combining the encoder and motor in a single unit, they have managed to create a very space-saving solution without compromising on functionality or accuracy.

-

EHM07-3B

Type: Incremental

Technology: Optical

Pulses per revolution: Min: 256 Max: 1024

Diameter: 16 mm -

ETD10-2C/D/E

Type: Incremental

Technology: Optical

Pulses per revolution: Min: 128 Max: 512

Diameter: 10 mm -

ETD12-2C/D/E

Type: Incremental

Technology: Optical

Pulses per revolution: Min: 128 Max: 512

Diameter: 10 mm -

ETD16-2D/E/F

Type: Incremental

Technology: Optical

Pulses per revolution: Min: 256 Max: 1024

Diameter: 16 mm

An encoder is a device that translates motion or position into digital signals. In motor control, encoders are used to measure speed, angle or position with high precision, which is crucial for precise control in automated systems. The process itself is called “encoding”, where information is converted into a specific data format according to predetermined rules. This technology is necessary for applications such as image compression, data security and motion capture.

Orbray encoders come in two main variants, magnetic and optical, depending on the detection principle used. The magnetic type is based on a sensor that senses changes in the magnetic field and converts these into output signals. The optical variant uses a code disc with reflective and non-reflective patterns and an integrated transmitter and receiver unit that creates signals in time with the rotation of the motor.

The encoder solutions are available in different resolutions and can be delivered with two or three channels. The resolution varies from 64 to 1024 pulses per revolution, depending on the model and size. To ensure the highest performance, some models may require adaptation depending on the motor series they are to be combined with. It is important to note that the encoders are only sold together with motors and not as stand-alone components.

Orbray encoders are ideal for applications that require accurate feedback of motion, such as in robotics, medical technology, automation and precision mechanical systems where precision and operational reliability are crucial.