Gearheads

By combining micromotors with gearheads, the motor speed can be reduced and the torque increased, making it possible to use compact motors in applications that require high force or precise movement. Orbray offers a wide range of high-precision gearheads, developed using the same advanced machining technology used in the manufacture of watch components and diamond tools. The result is quiet, efficient and highly reliable gear solutions for micromotors.

-

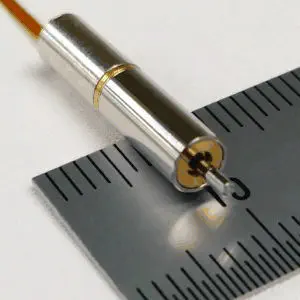

Gear head SPG07

Type: Planetary Gearbox

Shaft Direction: Coaxial

Shaft Configuration: Solid Shaft

Torque: 0 – 0.1 Nm

Configuration: Compact -

Gear head SPG10

Type: Planetary Gearbox

Shaft Direction: Coaxial

Shaft Configuration: Solid Shaft

Torque: 0 – 0.1 Nm

Configuration: Compact -

Gear head SPG12

Type: Planetary Gearbox

Shaft Direction: Coaxial

Shaft Configuration: Solid Shaft

Torque: 0.1 – 0.2 Nm

Configuration: Compact -

Gear head SPG16

Type: Planetary Gearbox

Shaft Direction: Coaxial

Shaft Configuration: Solid Shaft

Torque: 0.1 – 0.2 Nm

Configuration: Compact -

Gear head SSG10

Type: Spur gear

Configuration: Compact

Number of stages: Multi-stage

Performance: High precision, low noise -

Gear head SSG12

Type: Spur gear

Configuration: Miniature

Number of stages: Multistage

Performance: Precision, low noise -

Gear head SSG15

Type: Spur gear

Shaft direction: Coaxial

Shaft configuration: Solid shaft

Torque: 0 – 0.1 Nm

Configuration: Compact -

Geared Motor BMN04-0829

Type: Planetary Gearbox

Shaft Direction: Coaxial

Shaft Configuration: Solid Shaft

Configuration: Compact

Gearheads – High precision, higher torque

Orbray gearheads come in two main variants: spur gears and planetary gears. Spur gears have a simple and robust design where the input and output shafts are parallel. They are particularly quiet and have low mechanical complexity, making them suitable for applications with limited space and moderate torque requirements.

Planetary gears, on the other hand, are designed for higher loads and performance. Here, the input shaft (motor shaft) and the output shaft are in line, which provides a compact and balanced power transmission. By distributing the torque across multiple gears (planetary gears), both higher torque and longer service life are achieved. Planetary gears are ideal when size, strength and precision must be combined – for example in medical technology, robotics and instrumentation.

Gearheads are available in a variety of sizes and ratios, from single-stage designs with low reduction ratios to multi-stage models with extremely high gear ratios and corresponding torque amplification. All gearheads are sold in combination with Orbray motors to ensure optimal performance and compatibility.

Whether the need is high speed with low load or low speed with high torque, Orbray's gearheads offer a flexible solution with a focus on miniaturization, efficiency and durability.